Evolving Safety

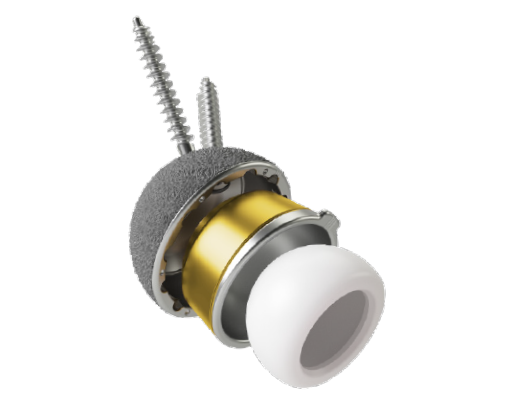

Mpact System is a comprehensive hemispherical cup platform featuring different shell and liner designs and materials allowing for efficiently treating the majority of the clinical cases from primary to revision surgeries, according to patients’ needs.

The Mpact system makes use of different advanced materials and manufacturing technologies.

Both MectaGrip and 3D Metal allow for designing and manufacturing implants featuring a high friction coefficient, increasing grip at the bone interface, thereby obtaining a superior primary stability.[2] Moreover, the porous structure parameters in line with the commonly accepted parameters[2,5] create a favorable environment for the bone.[6,7,8,9] The efficient connection with the bone has been validated by means of an animal study in young sheep.[2]

DISCOVER MORE ABOUT

MectaGrip is a porous coating treatment applied to the Mpact shells, consisting of a layer of commercially pure titanium deposited through a special Vacuum Plasma Spray technique (VPS). Titanium porous coating allows for an enhanced biocompatibility, thanks to the pure titanium composition and optimized porosity.

3D Metal is an advanced biomaterial structure that is finely engineered for the bone. It is made of Titanium alloy (Ti6Al4V), and it is obtained by means of 3D printing technology, an innovative one-step layer-by-layer additive manufacturing process (not a coating).

This advanced technology allows for designing different engineered 3D net structures starting from a CAD model in a precise, predictable and reproducible manner. By means of a single technology it is possible to efficiently face most clinical cases, from standard primary to complex revision surgeries.

No-Hole

Mpact No-hole

From size 46 mm to size 66 mm

Two-Hole

Mpact Two-hole

From size 46 mm to size 66 mm

Mpact 3D Metal Two-hole

From size 46 mm to size 66 mm

Mpact Multi-hole

From size 46 mm to size 76 mm

Mpact 3D Metal Multi-hole

From size 46 mm to size 72 mm

Mpact 3D Metal Multi-hole Thin

From size 48 mm to size 60 mm

The MULTI-HOLE SHELLS allow for the use of cancellous bone screws in 13 to 17 locations (size dependent) on the dome and equatorial region.

Mpact Rim-hole

From size 56 mm to size 76 mm

The RIM-HOLE SHELL allows for the use of cancellous and cortical bone screws.

CANCELLOUS BONE SCREW

Ø 6,5 mm from L 15 mm to L 70 mm

CORTICAL BONE SCREW

Ø 4 mm from L 25 mm to L 55 mm

Compatible with Mpact Rim-hole only

COMPRESSION POLYAXIAL LOCKING SCREW

Ø 6,5 mm from L 15 mm to L 70 mm

Compatible with Mpact 3D Metal Multi-hole only

(non-Thin version)

DM

Mpact DM

From size 42 mm to size 66 mm

SensiTiN DM Converter

TiN coated HNSS metal liner

(Titanium Nitride ceramic-like coating)

compatible with all Mpact System cups

Flat

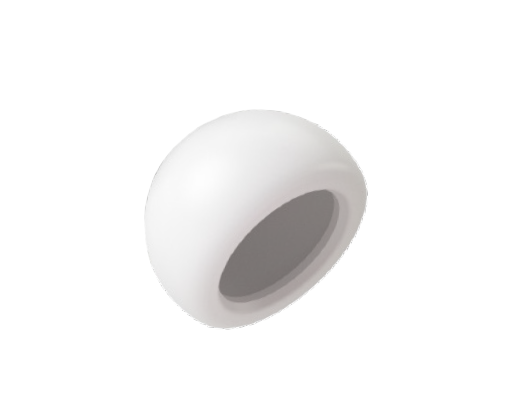

UHMWPE Highcross Liner

Hooded

UHMWPE Highcross Liner

Offset 4 mm

UHMWPE Highcross Liner

.

Face-Changing 10°

UHMWPE Highcross Liner

Double Mobility

UHMWPE Highcross Liner

The Clipping system for the polyethylene liners is placed outside the equatorial weight-bearing area in the thickest region of the liner.

This design reduces stresses at the liner/shell interface and minimizes the risk of the liner rim fracture in case of impingement.[1]

Therefore, the match between the anti-rotation tabs in the liner and the indentations on the shell limits rotational micro-movements and potential backside wear.[2,3]

The SensiTiN DM Converter tapered surface shows the same geometrical characteristics as the clinically successful Medacta ceramic liner. Micro-threads are also present on the tapered surface to increase stability of the device.

[1] Michael DR, MD, Review of the Evolution of the Cementless Acetabular Cup, ORTHOSuperSite December 1, 2008.

[2] Data on file Medacta.

[3] Y.K. Lee, K.C. Kim, W.L Jo, Y.C. Ha, J. Parvizi, K.H. Koo. Effect of Inner Taper Angle of Acetabular Metal Shell on the Malseating and Dissociation Force of Ceramic Liner. The Journal of Arthroplasty 2017 Apr; 32(4): 1360-1362.

[4] Y.K. Lee, J.Y. Lim, Y.C. Ha, T.Y. Kim, W.H. Jung, K.H. Koo. Preventing ceramic liner fracture after Delta ceramic‑on‑ceramic total hip arthroplasty. Archives of Orthopaedic and Trauma Surgery 2021Jul; 141(7): 1155-1162.

[5] L. Dall’Ava, H. Hothi, J. Henckel, A. Di Laura, P. Shearing, A. Hart. Comparative analysis of current 3D printed acetabular titanium implants. 3D Printing in Medicine 2019; 5:15.

[6] P. Robotti, A. Sabbioni, L. Glass, B. George, Macroporous Titanium Coatings , by Thermal Plasma Spray, ITSC 2013, International Thermal Spray Conference, May 13 –15, 2013, Busan, Korea.

[7] J. E. Biemond et al, In vivo Assessment of Bone Ingrowth Potential of 3-Dimensional E-Beam Produced Implant Surfaces and the Effect of Additional Treatments by Acid-Etching and Hydroxyapatite Coating, J. Biomat. Appl, published on line January 27, 2011, 0885328210391495.

[8] R. Ferro de Godoy et al., In vivo Evaluation of Titanium Macro-Porous Structures Manufactured Through an Innovative Powder Metallurgy Approach. Proceedings eCM XIII: Bone Fixation, Repair & Regeneration, June 24–26, 2012, Davos, Switzerland.

[9] A. Goodship et al, In-vivo Assessment of the Ingrowth Potential of Engineered Surface Topographies Produced by Spark Plasma Sintering, Proceedings 9th World Biomaterial Congress, June 1-5, 2012, Chengdu, China.